1. Introduction

This series DC Contactor Relay is used to DC voltage power control fields, such as new energy vehicles, construction machinery, photovoltaic systems, wind power intelligent equipment, battery charging and discharging systems, charging piles, etc.

2. Features

• Sealed with high-strength epoxy resin, no risk of arc leakage, ensuring no fire or explosion within the service life.

• Potting with mainly nitrogen inert gas improves arc extinguishing performance and effectively prevents contact oxidation and burnout. The contact resistance is low and stable, and the contact part can meet the IP67 protection grade.

• 200A 85ºC long time current carrying capacity.

• The insulation resistance reaches 100MΩ (1,000VDC), and the withstand voltage between the contact and the coil is 3.5kV.

• Compliant with IEC 60664-1, GB/T14048.1 and GB/T14048.4 requirements.

• Compliant with RoHS (2015/863/EU), REACH (1907/2006/EC) requirements.

• Safety certificate: CE, CCC.

3. Specification

|

Main Contact Specifications |

|

|

Contact Arrangement |

1K (1NO) |

|

Contact Polarity |

Non-polarity |

|

Contact Resistance |

≤0.5mΩ (at 300A) |

|

Max. Switching Voltage |

1,000VDC |

|

Max. Breaking Current |

2,000A (320VDC) 1 Ops |

|

Electrical Endurance (Resistive Load) |

3,000 Ops (1,000VDC 300A) |

|

5,000 Ops (750VDC, 300A) |

|

|

8000 Ops (500VDC, 300A) |

|

|

Mechanical Endurance |

300,000 Ops |

|

Withstand Current |

300A, Continuous |

|

400A, 60min |

|

|

500A, 5min |

|

|

600A, 1min |

|

|

Temperature Rise |

Main Contact Temperature Rise ≤45K (95mm2, 300A Continuous) |

|

Performance Parameters (at 23℃) |

||

|

Pickup Voltage |

See Coil Parameter Tables |

|

|

Dropout Voltage |

See Coil Parameter Tables |

|

|

Pickup Time |

≤25ms |

|

|

Contact Bounce Period |

≤5ms |

|

|

Dropout Time |

≤6ms |

|

|

Dielectric Strength |

Between Main Contacts |

12,000VDC 1min |

|

Between Main Contacts and Coil |

3,500VDC 1min |

|

|

Insulation Resistance |

Initial State |

100MΩ 1min |

|

After Electrical Life |

50MΩ 1min |

|

|

Shock |

Stability |

20g (Power On) |

|

Strength |

50g |

|

|

Vibration |

10g, 10~500Hz, 1/2 Sine Wave (Power On) |

|

|

Relative Humidity |

5%~95%RH |

|

|

Temperature |

-40℃~85℃ |

|

|

Load Terminal |

M8 External Thread |

|

|

Weight |

About 480g |

|

|

Dimension |

80mmx65.5mmx72.5mm |

|

|

Auxiliary Contact Parameters |

|

|

Aux. Contact Arrangement |

FK/FB/FZ (1NO/1NC/1CO) |

|

Aux. Contact Rated Current |

5A |

|

Aux. Contact Max. Breaking Voltage |

120VDC |

|

ADH300E Coil Parameters |

|||||

|

Coil Voltage |

Pickup Voltage VDC |

Dropout Voltage |

Coil Resistance |

Starting Power |

Holding Power |

|

9-36V |

9-36V |

5-7V |

3.5Ω±10% |

25W±10% |

2W±10% |

|

ADH300W Coil Parameters |

|||||

|

Coil Voltage |

Pickup Voltage VDC |

Dropout Voltage |

Coil Resistance |

Starting Power |

Holding Power |

|

32-96V |

32-96V |

16-20V |

40.5Ω±10% |

25W±10% |

2W±10% |

|

ADH300D Coil Parameters |

||||||

|

Coil Voltage |

Pickup Voltage |

Dropout Voltage |

Coil Resistance |

Starting Power |

Holding Power |

|

|

Starting |

Holding |

|||||

|

12V |

≤70%Us |

5%-40%Us |

2.5Ω±10% |

48Ω±10% |

60W±10% |

3W±10% |

|

24V |

≤70%Us |

5%-40%Us |

10Ω±10% |

190Ω±10% |

60W±10% |

3W±10% |

|

48V |

≤70%Us |

5%-40%Us |

40Ω±10% |

768Ω±10% |

60W±10% |

3W±10% |

|

60V |

≤70%Us |

5%-40%Us |

62.5Ω±10% |

1,200Ω±10% |

60W±10% |

3W±10% |

|

72V |

≤70%Us |

5%-40%Us |

90Ω±10% |

1,730Ω±10% |

60W±10% |

3W±10% |

|

ADH300DE Coil Parameters |

||||||

|

Coil Voltage |

Pickup Voltage |

Dropout Voltage |

Coil Resistance |

Starting Power |

Holding Power |

|

|

Starting |

Holding |

|||||

|

12V |

≤70%Us |

5%-40%Us |

2.5Ω±10% |

48Ω±10% |

60W±10% |

3W±10% |

|

24V |

≤70%Us |

5%-40%Us |

10Ω±10% |

190Ω±10% |

60W±10% |

3W±10% |

|

48V |

≤70%Us |

5%-40%Us |

40Ω±10% |

768Ω±10% |

60W±10% |

3W±10% |

|

60V |

≤70%Us |

5%-40%Us |

62.5Ω±10% |

1,200Ω±10% |

60W±10% |

3W±10% |

|

72V |

≤70%Us |

5%-40%Us |

90Ω±10% |

1,730Ω±10% |

60W±10% |

3W±10% |

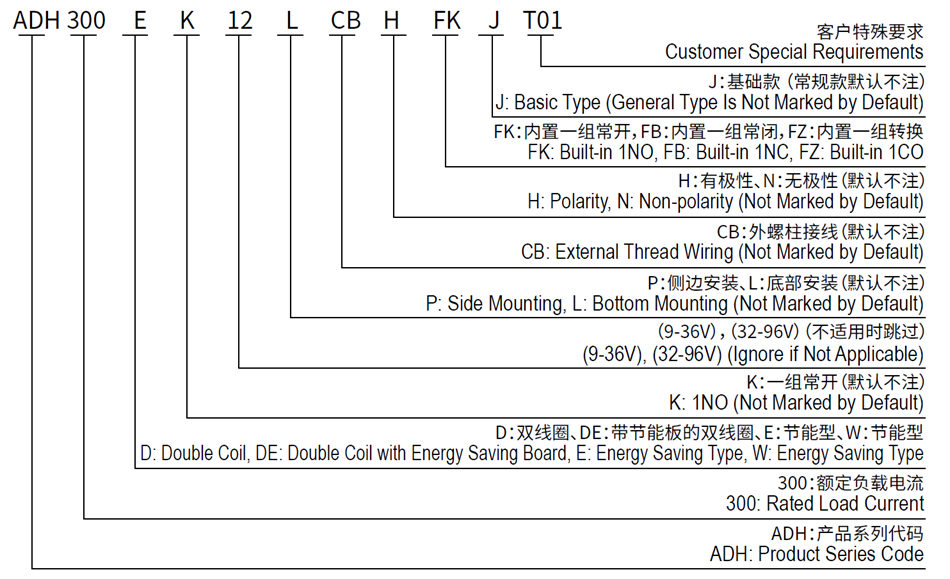

4. Model Coding

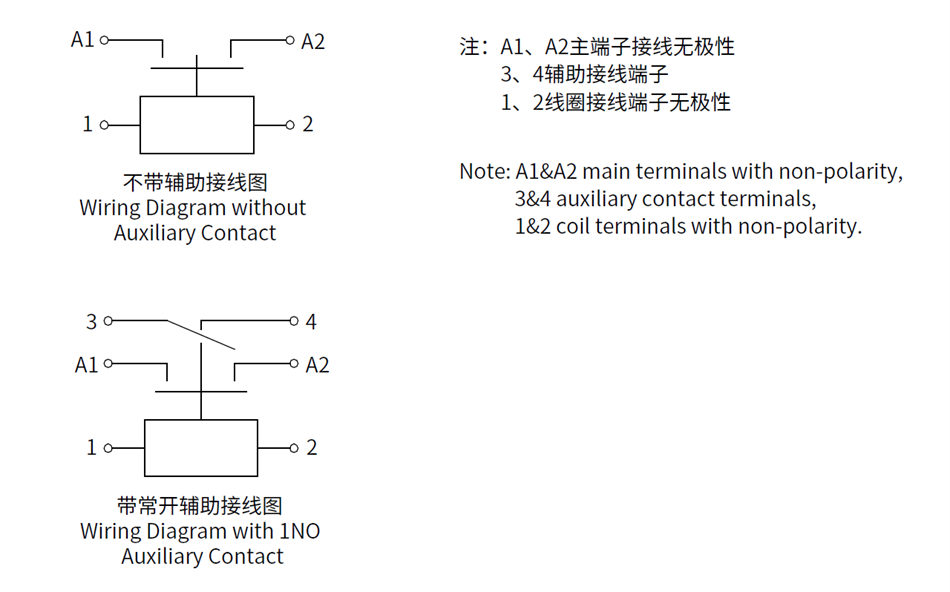

5. Wiring Diagram

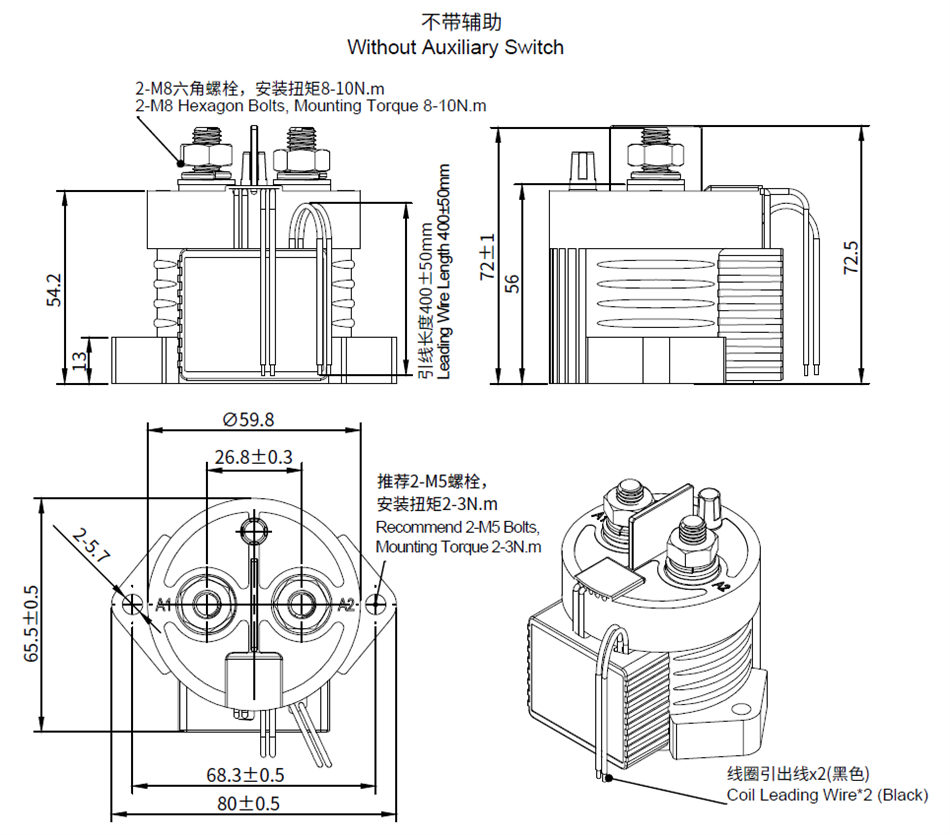

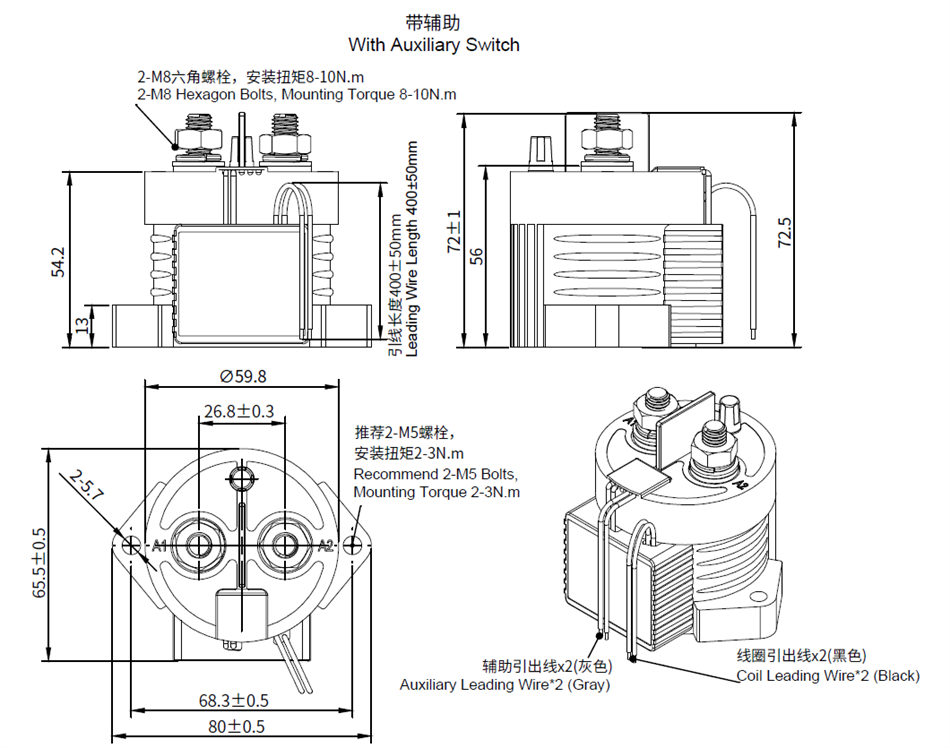

6. Outline Installation Dimension Drawing

Note: These datas are only for customer selection reference, AOKAI has tried the best to ensure the accuracy of the information. Product specifications and parameters may be changed due to product improvement etc., they may be inconsistent because of not updated in time. For the specific parameters and performance of each product, please refer to the samples provided by AOKAI and the corresponding signed and controlled specification.

English

English